Dry Ice Cleaning for Wood, Metal, and More

Dry ice blasting, also known as dry ice cleaning or CO2 (carbon dioxide) blasting, is quickly gaining popularity as an alternative to other cleaning methods. This method utilizes dry ice pellets propelled at high speeds from dry ice blasting equipment to clean surfaces without causing abrasion or leaving secondary waste, similar to laser cleaning. In this blog post, we'll explore the popular applications for dry ice blasting and highlight how the performance differs from other surface restoration methods like sandblasting or dustless blasting.

Understanding Dry Ice Blasting

Dry ice cleaning technology is a process that uses compressed air to accelerate dry ice pellets into a surface. Dry ice, the solid form of carbon dioxide, sublimates (turns into gas) upon impact, lifting contaminants without leaving behind a residue, profile, or secondary waste. This makes it an environmentally friendly and efficient cleaning technique, perfect for waste-sensitive blast settings or delicate materials. For a more in-depth look at the dry ice blasting process, check out this blog.

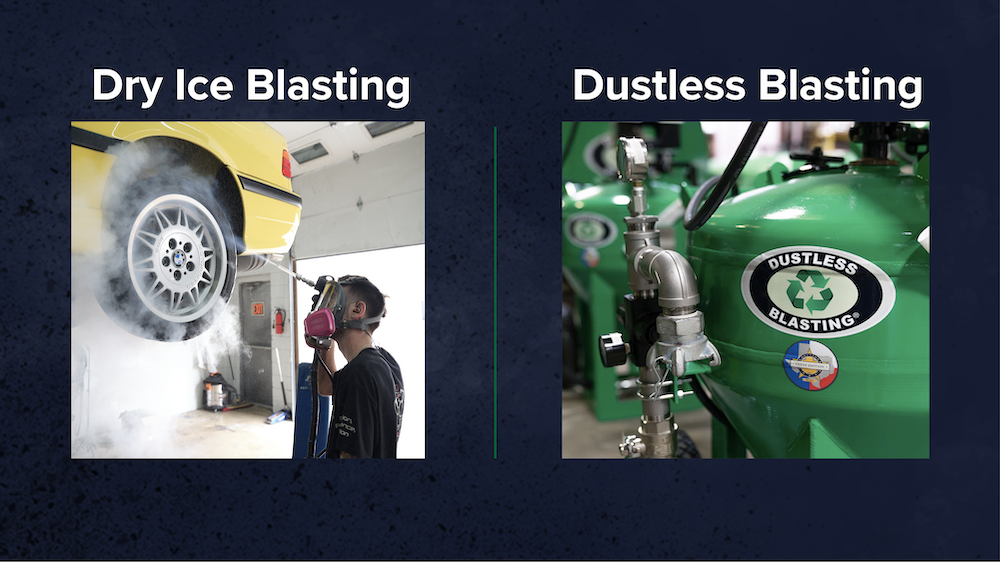

How Dry Ice Blasting Differs from Dustless Blasting

While dry ice blasting and dustless blasting are both popular cleaning methods, they have distinct differences. Dustless blasting uses a combination of abrasive media (like soda or glass beads) and water (if wet blasting) to clean surfaces. The ability to wet, dry, and soda blast in one Dustless Blasting machine opens the door for endless applications and versatility as the operator can tailor their sandblasting media and method for each unique project. This method is effective for heavy-duty cleaning but creates secondary waste and can require more cleanup.

In contrast, dry ice blasting utilizes CO2 (carbon dioxide) pellets and compressed air with dry ice blasting machines to clean and strip surfaces. The sublimation of the media eliminates the need for additional cleanup as there is no secondary media or water waste, making it ideal for sensitive environments where water or abrasive materials could cause damage or corrosion. Dry ice blasters are also gentle on surfaces and does not leave a surface profile. This is not ideal for all blast applications, but is perfect for delicate surfaces where no surface profile is needed.

Dry Ice Blasting Media

The most common forms of dry ice for blasting comes in either pellets or blocks, with the average cost of media totaling around $1-3 per pound. There are a few different cuts of dry ice you can purchase based on the machine you have and the project you're dry ice blast cleaning.

-

Pellets: Typically measuring about 1/8 inch in diameter, these are the most common form used in dry ice blasting. Pellets provide a good balance between aggressive cleaning power and surface protection, making them suitable for a wide range of applications.

-

Blocks: Larger blocks of dry ice can be crushed into various sizes before use. This form is particularly useful for heavy-duty cleaning tasks where more substantial ice fragments are needed to strip tougher contaminants or coatings.

-

Rice-Sized Particles: These small, granular pieces of dry ice are ideal for precision cleaning. They allow for detailed work on intricate and delicate parts, where minimal substrate impact is crucial for dry ice blast cleaning.

-

Micropellets: These are even smaller than standard pellets and provide a less aggressive cleaning action, suitable for extremely delicate or precision equipment.

Coupled with the fairly high price, dry ice requires extensive storage and handling care to minimize sublimation or operator injury. You'll have to be sure to coordinate your project timeline with your media purchase to ensure your main dry ice blasting technology doesn't sublimate before you can use it.

With the versatility of a dustless blaster, you have the freedom to wet, dry, and soda blast in one machine. This means your abrasive choices are virtually limitless and can be tailored to fit the target surface profile and removal rate of each individual project. A popular media choice, crushed glass, is around $0.10-0.30 per pound and does not require specialized storage to preserve abrasive integrity.

Applications of Dry Ice Blasting

Because the method of dry ice cleaning doesn't leave a surface profile, the project applications may be more limited to jobs that need a smooth surface finish. Let's take a look at some of the most popular applications for a dry ice machine.

- Rust Removal: Dry ice cleaning can remove surface rust and iron oxide from metal surfaces, preventing the rusting process from advancing. The lack of abrasive blasting media reduces the risk of pitting or other damage to metal. The cooling temperature of the dry ice also minimizes heat warping without the need for water.

- Metal Cleaning: A dry ice blaster is great for intricate metal detailing or plates. Without any secondary waste, it's easy to clean items such as an electrical panel or engine while preventing corrosion or preserving a contamination-sensitive environment like a food processing plant.

- Wood: Dry ice blasting is effective in removing paint and coatings from a variety of surfaces, including wood. It leaves a clean wood finish without damaging the underlying material. This method is particularly useful for delicate wooden surfaces where maintaining the integrity and appearance of the wood grain is essential.

- Mold Remediation: Due to the lack of secondary waste and deodorizing capabilities, dry ice blasting is highly effective in mold remediation. This method is especially valuable in spaces where the use of harsh chemicals is undesirable or prohibited for the environment you're blasting.

Rust Removal and Metal Cleaning

When blasting a rusted surface with dry ice, the extreme cold of the media, at -109.3°F/-78.5°C, induces thermal shock, which contributes to breaking the rust's bond with the metal through rapid temperature fluctuations, causing the rust to detach more easily. Because the process of dry ice blasting allows for ultra-precise cleaning, you can quickly blast detailed items such as a control panel or engine without introducing moisture, debris, or chemicals that may corrode the surface. Additionally, the lack of secondary waste makes dry ice the perfect application for businesses that want to avoid extensive cleanup of foreign material from a metal surface clean, such as a food processing plant.

.jpg?width=748&height=499&name=rust-on-the-back-door-of-trucks-rusty-smudges-at-2023-11-27-05-11-58-utc%20(1).jpg)

While dry ice blasting effectively removes light to moderate rust and grease, its capabilities may be limited when confronting larger project that need a specific surface profile or finish. In such cases, techniques like wet blasting with a rust inhibitor may be the way to go. This method not only strips away tougher rust but also better prepares metal surfaces for repainting or refinishing by creating a roughened surface profile, enhancing coating adhesion.

Wood Restoration

Dry ice cleaning wood surfaces is great for delicate applications such as antique furniture or carvings. It can safely remove layers of old paint, varnish, and other finishes without damaging the underlying wood or altering its character. This is crucial for preserving both the aesthetic and monetary value of antique items.

For larger surface areas, such as a log home, it may be more cost and time efficient to consider dry sandblasting options, such as corn cob. With the reusability of corn cob media, you can blast delicate wood surfaces at top speed while keeping project costs low. Check out the speed of a dustless blaster on this 5,000 sqft log home!

Another application for dry ice and wood is cleaning fire and soot damage. Along with the benefit of cutting back on cleanup without any secondary waste, dry ice helps to deodorize the soot smell, ensuring you have a well-rounded and effective fire restoration tool.

Depending on the project size, and if secondary waste isn't a project concern, it may be more cost-effective to utilize the soda blast function of your dustless blaster. Sodium bicarbonate media costs an average of $0.20-$0.60 per pound and has similar cleaning and deodorizing capabilities as dry ice media. Additionally, soda blasting is more readily available and can be a more practical choice for larger scale projects or when budget constraints are tight. Furthermore, it is gentle on most substrates, making it a versatile option for various restoration needs.

Mold Remediation

Dry ice blasters are effective for mold remediation on various surfaces, including wood, concrete, and tiles. This technique is particularly beneficial because it prevents additional moisture from being introduced into the affected area or air, which is crucial in mold remediation to avoid further mold growth. Dry ice blasting also reaches into small cracks and crevices where mold tends to thrive, which can be difficult to clean with chemical-based solutions. The speed and efficiency of this process not only thoroughly removes existing mold but also minimizes downtime in commercial settings or home environments, making it a great method for quickly returning areas to safe, clean conditions.

If dry ice blasting isn't an option for mold removal, you can read more about the effectiveness of soda blasting mold removal in this blog post. We highly recommend doing extensive research before completing any type of mold remediation and removal as some states may require extra certification and precautions before beginning this type of project.

Conclusion

Dry ice cleaning is ideal for applications where you want to avoid secondary waste or don't want to leave a surface profile on delicate materials. However, dry ice media can be costly and requires specialized storage conditions to preserve its integrity. Additionally, though preventing media waste is a huge positive for this method, many methods of surface cleaning require a specific surface profile that dry ice can't provide. With a dustless blaster's ability to wet, dry, and soda blast in one machine, you have the versatility and flexibility to tailor your blast method and media to suit virtually any project. This ensures you have the right tool for the job, no matter the job.

Book a meeting with our blast experts to talk about the best surface cleaning methods for your upcoming project today!