Comparing Dry Ice Cleaning to Dustless Blasting

What's the difference between Dustless Blasting and Dry Ice Blasting? Here is the basic rule to keep in mind:

Dry Ice Blasting = Tool for Cleaning

Dustless Blasting = Tool for Cleaning and Removal of Tough Coatings

Let's take a look at dry ice blasting, how it works, its advantages and disadvantages, and finally — which method is better for your project's needs.

How does the Dry Ice Blasting Method Work?

A dry ice blasting machine works by ejecting solid carbon dioxide pellets at incredibly high speed. When the pellets hit a surface, they sublimate, or evaporate into a gas. The intense temperature change helps remove accumulated contaminants on the substrate.

The Benefits of Dry Ice Blasting

Gentle on surfaces

Dry ice cleaning is a nonabrasive cleaning method. When used correctly, dry ice blasting equipment allows the removal of contaminants without damaging the structural material underneath. Similar to laser cleaning, this method is especially valuable for remediation and restoration projects.

No secondary waste

Since the dry ice sublimates on impact, there is no secondary waste produced. Cleanup of the dislodged media (or primary waste) is still necessary but will likely be less of an intense process compared to other methods.

Non-conductive and non-toxic

The unique properties of dry ice make it an ideal cleaning solution in a variety of commercial and manufacturing settings. Food processing companies benefit from the increased productivity that comes with being able to clean their equipment even while its still running. Electronic service centers benefit from a cleaning method that is non-conductive and residue-free.

“Since the paint removal by dry ice has no abrasive effect, mechanical damage to boards are avoided. The component-accurate repair of coated components was not possible before the introduction of dry ice blasting. After the repair is carried out, the parts will be partially painted new and the components are delivered to the customer in their original state."

-Stefan Berger. See the Cold Jet case study here.

The Drawbacks of Dry Ice Blasting

High Costs

One of the biggest disadvantages is that dry ice is incredibly expensive — not only to buy but also to store. Dry ice requires temperatures less than -78.5 degrees Celsius to store long term, requiring special storage equipment that can cost tens of thousands of dollars. And because dry ice machine parts can often be proprietary to the manufacturer, maintenance and repair costs can be unforgiving.

Lacks Power

While some applications greatly benefit from dry ice's gentle touch, it lacks the power and flexibility to meet the needs of tougher jobs, like removing tough coatings over a large surface area. With dry ice's already high costs, using dry ice in a less than ideal scenario can result in a significant dip in productivity, resulting in unsustainable operating costs compared to other methods.

Safety Risks

Within enclosed spaces, dry ice blasting can cause a dangerous buildup of carbon dioxide in the air. The operator or any employees in the surrounding area may experience asphyxiation. A well-ventilated space is required to operate dry ice blasters safely.

Dry ice blasting can be extremely cold and noisy. Any persons in the surrounding area will need to wear multiple layers of PPE — including gloves, jackets, and earmuffs — to keep them warm and safe.

An unclear future

Laser cleaning technology, a growing surface cleaning method, shares many of the same strengths as dry ice blasting equipment in addition to being faster. Understandably, that's all that many manufacturing companies have needed to hear to make the switch to the newer technology.

Learn more about Laser Cleaning vs. Dustless Blasting here.

Dustless Blasting v. Dry Ice Blasting: Which One Should I Pick?

It's clear that while cleaning with dry ice isn't appropriate for every job or business, it can really excel in certain applications. If you're considering incorporating dry ice blasting cleaning to your business, ask yourself these questions:

WHAT ARE YOU TRYING TO ACHIEVE?

If you're looking to remove thin layers of contaminant like mold or food grease without damaging the underlying surface, dry ice blasting is a great option. However, you might also want to consider soda blasting as a cheaper alternative or laser cleaning as a more expensive alternative suited for larger scale industrial applications.

In our experience, tough jobs often pay the most. If you need to remove tough, thick coatings over a large area, traditional removal methods like abrasive blasting are a more economical choice.

HOW MUCH MONEY ARE YOUR CLIENTS WILLING TO SPEND?

Operating and maintaining dry ice blasting equipment is expensive. If your clients aren't willing to pay the extra costs that come with using dry ice, it may not be the right choice for you. Consider whether the advantages listed above outweigh the disadvantages for your specific needs. If you don't need a dry ice blaster very often, save some money and consider a dry ice blaster for rent rather than purchase.

DOES THE SUBSTRATE NEED AN ANCHOR PROFILE?

The anchor profile or anchor pattern refers to a series of “peaks and valleys” that exist on a substrate. This surface roughness, often microscopic in scale, is extremely important to ensuring that new coatings adhere properly. Because dry ice blasting is a non abrasive cleaning method, it will not profile the surface being cleaned. If you're in the business of preparing surfaces for recoating, you'll want to consider other methods that can leave behind a profile as it cleans.

With an abrasive blasting machine like one of our blast pots, you can clean a surface and create an anchor profile all in one step. This makes it a much more efficient and effective preparation solution for many businesses.

Which is the smarter business investment?

For startups

The answer is simple. If you're looking to get into the restoration business, Dustless Blasting is the smarter and more versatile investment. The service is in higher demand and the machine is better suited to handle a larger number of jobs across many industries.

For existing businesses

Consider whether soda blasting, a cheaper alternative to dry ice, is better for your needs. Many of the same applications that dry ice is advertised for can also be completed with a soda blasting machine at a far lower operating cost. For example, Dustless Blasting business owners are regularly utilizing soda blasting to clean soot off of fire-damaged buildings and clean food-grade surfaces.

Learn More about Soda Blasting: Soda Blasting v. Sandblasting

Heres what some of our contractors have to say about dry ice blasting:

I independent contract for a dry ice company besides my blasting. It's painfully slow and expensive. Biggest advantage is the cleanup factor but takes 2 guys to run.

-Rob L.

I did a demo with a company out of Alabama. It cleaned well but didn’t remove paint or dirt/grime like I would expected. Extremely expensive and somewhat limited on the dry ice pellets (at least in my area).

-Richard S.

I have used it. Complete different machine. It is good for cleaning but you need a storage unit for the ice.

-Luke H.

Ya it's a completely separate piece of equipment. However, I believe the compressor will have enough power to attach a dry ice blaster and run it off of your existing platform. We looked into adding one for certain applications, but dislike the fact that you can't store the media longterm so no bulk discounts really. Still a nice piece of equipment to add to the arsenal!

-Tyler S.

The Dustless Blasting Opportunity

If you're ready for a change and want to control your future – Dustless Blasting is pioneering a brand new industry – mobile blasting and cleaning. With versatile equipment that is made to move, you can offer a wide variety of onsite services.

Here is what inspired us to create this exciting business opportunity:

-

Revenue Potential: The mobile paint stripping and cleaning industry is valued at over $10 billion annually, with strong year-over-year growth.

-

High Demand: Look around. Everything is painted, rusty, or dirty. The demand for this service is everywhere, but providers are few and far between.

-

Low Overhead / Startup Costs: You can start a business for around $50,000!

-

Not Time Consuming: You can be operational in days — not weeks or months.

-

High Margins: Need we say more?

-

Scalable Growth: It’s easy to scale your business by adding trailers and crew as you grow.

-

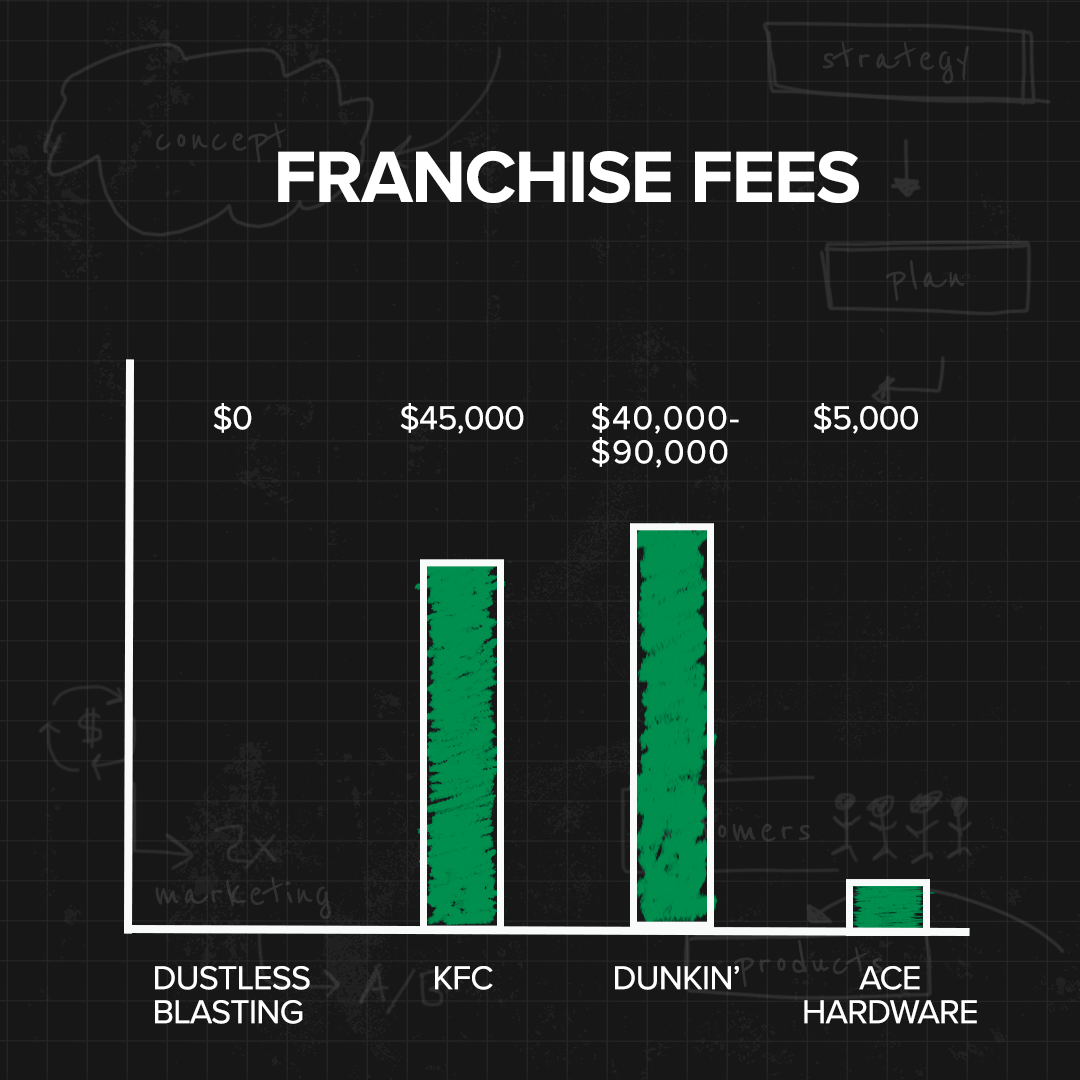

Smart Risk: We give you the best of both worlds. Benefit from a community of business owners, marketing support, and a trusted brand to help you succeed — all without franchise fees.

Did we mention it's not a franchise?

You work hard for your money, so we believe you should keep all the profits.

-

No ongoing fees

-

No corporate limitations

-

No territories

-

Keep 100% of your profits

We believe in setting you up for success, so you can count on training, support, marketing materials, and advertising services.