What is media blasting?

Media blasting is a highly effective surface restoration process that employs the use of sand blast media to cleanse, smooth, or remove unwanted coatings. In addition, media blasting can be utilized for shaping and texturing metal components before welding and repainting. This versatile technique is applied across a multitude of industries, such as automotive, ship maintenance, concrete restoration, construction, and manufacturing.

Dustless Blasting is a leading innovator in the media blasting industry and has gained significant popularity among professionals due to its exceptional efficiency and eco-friendly characteristics. Dustless Blasting provides an extensive range of blast pots in varying sizes, along with trailer mounted machines and compressors. For those interested in incorporating media blasting equipment into their current business or starting a new business venture with a mobile trailer, Dustless Blasting is the ideal starting point.

Choosing Media Blasting Equipment

To perform an abrasive blasting job efficiently and safely, you need to have the right equipment. Not all media blasting systems are created the same. In fact, choosing the right equipment for the jobs you pursue is crucial in the success of your projects.

Here are some questions to ask yourself when choosing a media blaster:

1. How versatile of a media blaster do you need?

When considering media blasting equipment, it's important to understand which method is most suitable for your needs. While some blasters may only be capable of dry blasting with a limited range of materials, others offer the flexibility to employ soda and wet blasting too - taking on more applications than ever before! So take time to figure out what process best fits you project requirements. Luckily, Dustless Blasting equipment is capable of performing all three methods - dry blasting, wet blasting and soda blasting. This is why professionals in all industries consider our machines the must-have surface restoration equipment.

2. Do you have access to a compressor that meets the cfm requirements of the media blaster?

Every media blaster requires a powerful compressor to deliver the sand blast media out of the machine and effectively remove the unwanted coating. When choosing a media blaster, it's important to consider the other must-have components like the compressor. If you have access to a powerful compressor, note the CFM and go with a media blaster that pairs appropriately with it. If you don't have a compressor, consider going with our portable systems that come with a media blaster and a perfectly paired compressor.

3. Do you need a portable media blaster?

Media blasting equipment varies in size and mobility. Are you blasting small parts in a shop that can fit in a sand blasting cabinet? Or are you blasting large buildings, boats, vehicles and concrete spaces that require a mobile media blaster? If you're cleaning small parts, a blasting cabinet might be the better option. If you are blasting a variety of products in all different sizes, one of our standalone blast pots might be perfect for shop use. If you need to easily transport all your blasting equipment directly to the job, our mobile blasting systems are the way to go!

Below is a list of the very basic components required for media blasting. If you are interested in reading about more about necessary media blasting equipment or want to take an in-depth look at the items listed below, read this article.

Blast Pot

At the heart of media blasting equipment is the blast pot, which uses an air stream to distribute abrasive media for breaking down surface materials. Media blasters come in various sizes and are capable of different methods, as we discussed earlier. Identify what you'll be blasting, what compressor size you have and if you need to be mobile when choosing your blast pot.

Dustless Blasting machines offer the versatility of wet, dry, and soda blasting in a single, easy-to-use device. Adding water to the blast pot suppresses dust, reducing the need for containment and making cleanup easy. This also enables blasting in open environments, even if there are others working nearby. A wide selection of sand blast abrasives and the ability to adjust pressure and flow make it suitable for any substrate.

An Air Compressor

For a successful blasting project, it's important to obtain an air compressor that meets the required level of cubic feet per minute (CFM) to properly power your blast pot. When selecting a blast pot, make sure to notice the CFM requirement so that you can purchase the right compressor.

Air Drying & Cooling System

This equipment is paired with a media blasting system to remove water from compressed air before it enters the pressurized blast tank when dry blasting. Compressed air moisture can obstruct blast pots and compromise the quality of the substrate by reintroducing moisture to the surface. This highly effective moisture trap uses two-stage filtration, cyclone separation, and residual filtration while ensuring minimal pressure drop.

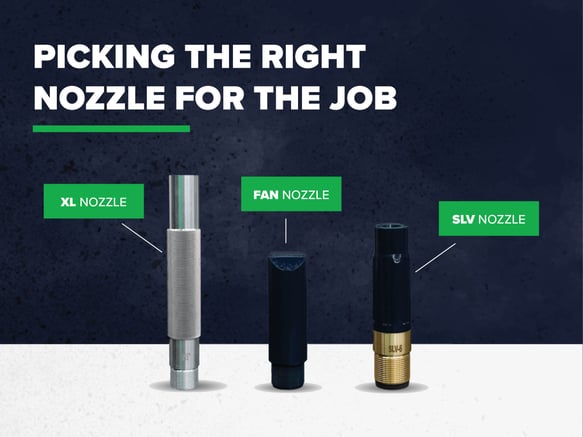

Media Blasting Nozzles

The nozzle guides the abrasive media through an air stream to the targeted surface, where the abrasive will remove the unwanted coating. Each nozzle has it's own unique pattern, and can be more or less effective than it's counterparts depending on the kind of project. It is essential to recognize the function of each and determine whether it is the optimal selection for your next job. To learn more about selecting the right nozzle, read this blog post.

Find out more about media blasting equipment and which system might be best for you in this guide.

Picking the right Sand Blast Media for your job

When choosing your sand blast media, just as with selecting your nozzle, it is crucial to take into account the specific requirements of the job you have ahead of you. The material of the substrate, the location of your blast, the desired surface cleanliness and the thickness of the coating are a few of the major elements that play a part in selecting the right abrasive. The most significant factor to consider when selecting an abrasive is whether you will be dry blasting or wet blasting. Here a few of the most popular abrasives for dry and wet media blasting.

Dry Blasting Abrasives

Sugar Sand

Sugar sand is a round media used for light duty dry blasting, cleaning and stripping coatings – particularly when a smooth finish and minimal damage to the substrate are desired.

Corn Cob

Corn cob is made from crushing the woody ring of a corn cob into multiple sizes. It is an organic, soft media ideal for delicate surfaces like wood.

Sodium Bicarbonate

Sodium bicarbonate is a mild abrasive that won't damage delicate substrates. Soda blasting is great for cleaning and fire restoration jobs.

Wet Blasting Abrasives

Steel Shot

Steel shot blast media is wildly used for cleaning, polishing, peening and descaling.

Coal Slag

Coal slag is an angular blast media that is a byproduct of coal. This abrasive is used to remove coatings like rust and paint from steel and concrete.

Crushed Glass

Crushed glass blast media is free from crystalline silica and made from 100% recycled glass. It produces a cleaner finish than most slags and is very cost conscious.

Read more about all the different kinds of media blasting abrasives and how to choose which one is best for your job in this blog post.

industries that need media blasters

With the ability to remove unwanted coatings from a variety of surfaces, media blasting machines like the Dustless Blaster are commonly used for cleaning or stripping cars, pools, ships, concrete, buildings, and more. Various industries rely on media blasters and because almost every surface has some form of coating, the list of potential clients is endless! To view the entire list of media blasting applications, click here.

Automotive Industry

Media blast pots are an essential tool for any auto body shop or collision repair centers, facilitating rust removal, paint stripping, and other necessary operations. With the availability of these tools, technicians are able to expedite their projects while simultaneously optimizing cost efficiency, resulting in expedited project turnaround times and enhanced output quality. Both existing automotive businesses and startup media blasting business owners have found incredible success with their Dustless Blasting systems.

Marine Industry

Fire Restoration

Soda blasting provides a fast, efficient, and eco-friendly solution for fire damage restoration. Soda blasting also neutralizes odors caused by smoke, as the sodium bicarbonate particles absorb and eliminate the odor molecules. These factors plus more have made soda blasting the go-to method for repairing any fire damaged materials.

Here are a few other uses for media blasting:

- Concrete restoration

- Line stripe removal

- Graffiti removal

- Fleet restoration

- Powder coat removal

- Pool cleaning and plaster removal

- Wood restoration

- Antique restoration

- Rust removal

- Industrial equipment

For more in-depth information on each of these media blasting applications, checkout this blog.

media blasting FAQs

What is the difference between sandblasting and media blasting?

The term "sandblasting" was popularized when silica sand was the go-to choice for blast cleaning work. Nowadays, with what we know about silicosis, the surface preparation industry has largely moved away from using silica sand as an abrasive choice. It's still common, however, to hear people refer to media blasting or dry abrasive blasting as "sandblasting".

What's the Difference Between Media Blasting and Soda Blasting?

Soda blasting, also known as sodium bicarbonate (baking soda) blasting, is a type of media blasting process that uses baking soda particles to clean surfaces. The baking soda will help to clean underneath the coatings as it takes away the unwanted top layers of contaminants. In addition, sodium bicarbonate has a relatively low Mohs hardness of 2.5 which means it is one of the gentler abrasives out there.

Learn everything you need to know about soda blasting with our Ultimate Guide to Soda Blasting.

How many times can you reuse blast media?

The number of times you can reclaim and reuse spent media depends on the type of media and what you've been blasting. Some types of sandblasting media, such as aluminum oxide and silicon carbide, can be reused many times before needing to be replaced. Other types of blasting media, such as copper or nickel slag, break down too quickly to for reclaiming to be worth the extra effort.

Even if you can reuse blast media, it doesn't mean you always should. The characteristics of your abrasive media (mesh size, shape, and hardness) may change from one use to another. For instance, if you're using an angular abrasive like crushed glass to cut through a tough coating and profile the substrate, upon reclaiming that same media, you may not find it to be as effective as the first time you used it.

If we missed one of your biggest questions, you can find the full list of our most frequently asked media blasting questions here.

Are you ready to learn more about Dustless Blasting machines and take the next step in media blasting? Click our free resource below!

.jpg?width=508&height=381&name=Scotts%20Sandblasting%20and%20Painting%20wood%20blasting%20(1).jpg)