Picking the correct nozzle can go a long way on the blast site. When you’ve got a big project with a lot of surface area, there are nozzles that produce a wider spread to help you cover as much of that area in as little time as possible. There are nozzles for projects with more delicate substrates, as well as nozzles that will help you retain media when blasting small or thin surfaces as well. So let’s get into the specifics and talk about which nozzles will help you get your job done as efficiently as possible.

Nozzle Shapes

The shape of a nozzle’s ‘bore’ is what determines the blast pattern.

There are two primary types of nozzle bores; Straight and Venturi. A straight bore will create a tight blast pattern that helps with smaller jobs where the blasting will need to be more precise, such as the thin metal bars on chairs or handrails.

A Venturi bore creates a wider blast pattern and helps to increase the velocity of the abrasive as it leaves the nozzle. Both of these qualities that the venturi nozzle has is what helps it to be a more efficient nozzle for larger jobs with a lot of surface area.

Nozzle Types

Here’s a quick video introduction to all of the nozzles that are carried in the Dustless Blasting Online Store.

SLV Nozzles

The ‘Standard Long Venturi’ Nozzle creates a large circular blast pattern that makes it an incredibly versatile nozzle that would make for a good choice in almost any situation.

Fan Nozzles

The Fan Nozzle creates a very thin oval shape which makes for a wide, sweeping style of removal. By widening the area of the blast pattern, The force of impact from the media onto the surface is lightened. This is ideal for brush-off blasting or other applications where low impact is desired.

ST Nozzles

ST Nozzles provide a very tight and concise stream of blasting media. This is great for precision work, such as getting into any remaining corners, nooks, crannies, or hard to reach areas of a project after the brunt of the work has been completed. The condensed stream means little media is wasted as well.

XL Performance Nozzles

XL Performance nozzles boast an increase in abrasive particle velocity, which results in improved production rates and efficiencies. Part of the efficiency is the ability to use a larger standoff distance, which will allow for the stream of media to grow wider, thus letting you cover more of your project in less time.

Nozzle Size and Your Air Supply

Nozzles are measured by their inner diameter, which is expressed as a number. The number size represents 1/16" increments. For instance, a #5 nozzle has a 5/16" inner diameter while a #6 nozzle has a 3/8" (6/16”) inner diameter.

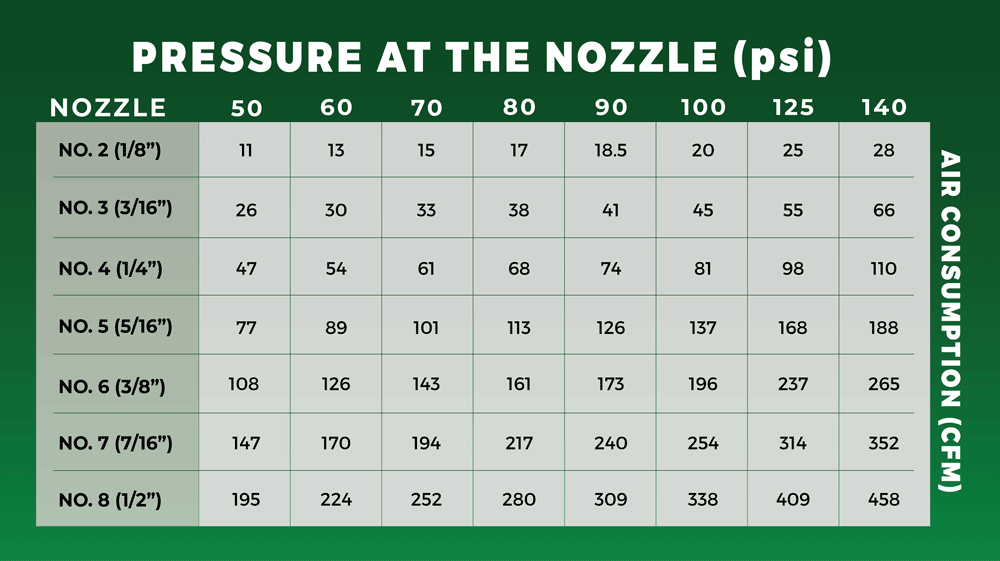

To find your most productive nozzle, determine the following:

- What volume of air your available compressor can supply per minute (CFM)

- Your desired nozzle pressure (PSI) you want to maintain for productive blasting

Next, consult the chart to find the nozzle orifice size that meets those parameters.

Wear Increases Nozzle Size

Abrasive passing through the nozzle will wear away the lining, enlarging the orifice. This is unavoidable. A worn nozzle requires more volume per minute to maintain your target pressure.

To see just how much wear your nozzle has been through, you can use the drill bit test. If a 3/8" drill bit will pass through your #5 nozzle, it is now worn down to a #6. If a 7/16" bit fits through it, it's now a #7 and so on.

Nozzle Wear

Nozzles wear down over time, it’s important to think about how you use your nozzles to help determine how long your nozzles may last.

Have you noticed that you are running out of abrasive quicker?

Does it feel like you aren't making progress on your jobs as fast as you used to?

Check your nozzles for wear. There are some obvious signs that your nozzle is wearing down, it might have some small cracks or could even be making a high pitched whistle sound as you use it. There are more subtle signs of nozzle wear you might not be looking for too. Test to see if your nozzle is starting to wear out by measuring the size of the ID with a drill bit. If you own a No. 5 nozzle (5/16" ID), and you are able to pass a 3/8" drill bit through it, then your nozzle has been worn out and will need replacing.

If you primarily use your Dustless Blasting machine to wet blast, then your nozzles will last for a good amount of time, up to multiple years. The water mixed with the abrasive helps to reduce friction inside the nozzle and keeps it in better condition for longer. We are unable to tell you exactly how long your nozzle's lifespan is because of all the different factors that need to be considered. How often you dry blast, the size and grit of the abrasive you use, the frequency at which you use your machine and nozzles all factor into the wear down rate.

What's so bad about a worn down nozzle?

When you use a worn down nozzle you are going to consume media at a much faster rate than you should. There will be a lot of excess spent media. You will work slower and use more media than you need to, meaning your profit margins will plummet as you buy more abrasive than necessary for each job and buy more fuel to keep your compressor running for longer than the job would otherwise take.

Where can I purchase nozzles?

If you're looking to add some new nozzles to your arsenal, or you need a fresher version of one you've been using for awhile, then check out the Dustless Blasting Online Store! You'll be able to find any nozzle you might need no matter the size of your DB Machine!.