Explained: Vapor Blasting/Vapor Honing, Venturi, Slurry & Dry Blasting

When you think of blasting method terms for surface restoration, you may think of sandblasting, soda blasting, abrasive blasting, vapor blasting, vapor honing and more. These terms are typically used interchangeably, but what's the difference? In this blog, we'll do a deeper dive into the top technologies used in the surface restoration industry and help categorize these terms to get you blasting rust, aluminum, or paint like a pro.

Separate by Technologies

There are many types of technologies in the surface preparation and restoration industry. To keep this blog from turning into a novel, we're focusing on four core blasting technologies or methods.

Water + Abrasive Methods

-

Venturi Blasting

-

Vapor Blasting/Vapor Honing

-

Slurry Blasting

Abrasive-only Method

-

Dry Blasting

Technology Sub Categories

Separating surface preparation methods by overarching technology gives room to break technologies into sub categories with other commonly used terms like sandblasting, wet blasting, or soda blasting. That would look something like this:

Water + Abrasive Methods

Venturi Blasting

- Wet blasting

- Wet abrasive blasting

- Wet media blasting

- Dustless Blasting

- Dustless sandblasting

Vapor Blasting/Vapor Honing

- Aqua blasting

- Liquid honing

- Wet blasting

- Wet abrasive blasting

Slurry Blasting

- Wet blasting

- Wet abrasive blasting

- Wet media blasting

Abrasive-Only Method

Dry Blasting

- Sandblasting

- Soda blasting

- Media blasting

- Abrasive blasting

- "X media that doesn't sink in water" + blasting

You get the drill now! With the picture painted, let's get into the differences among the four blasting technologies.

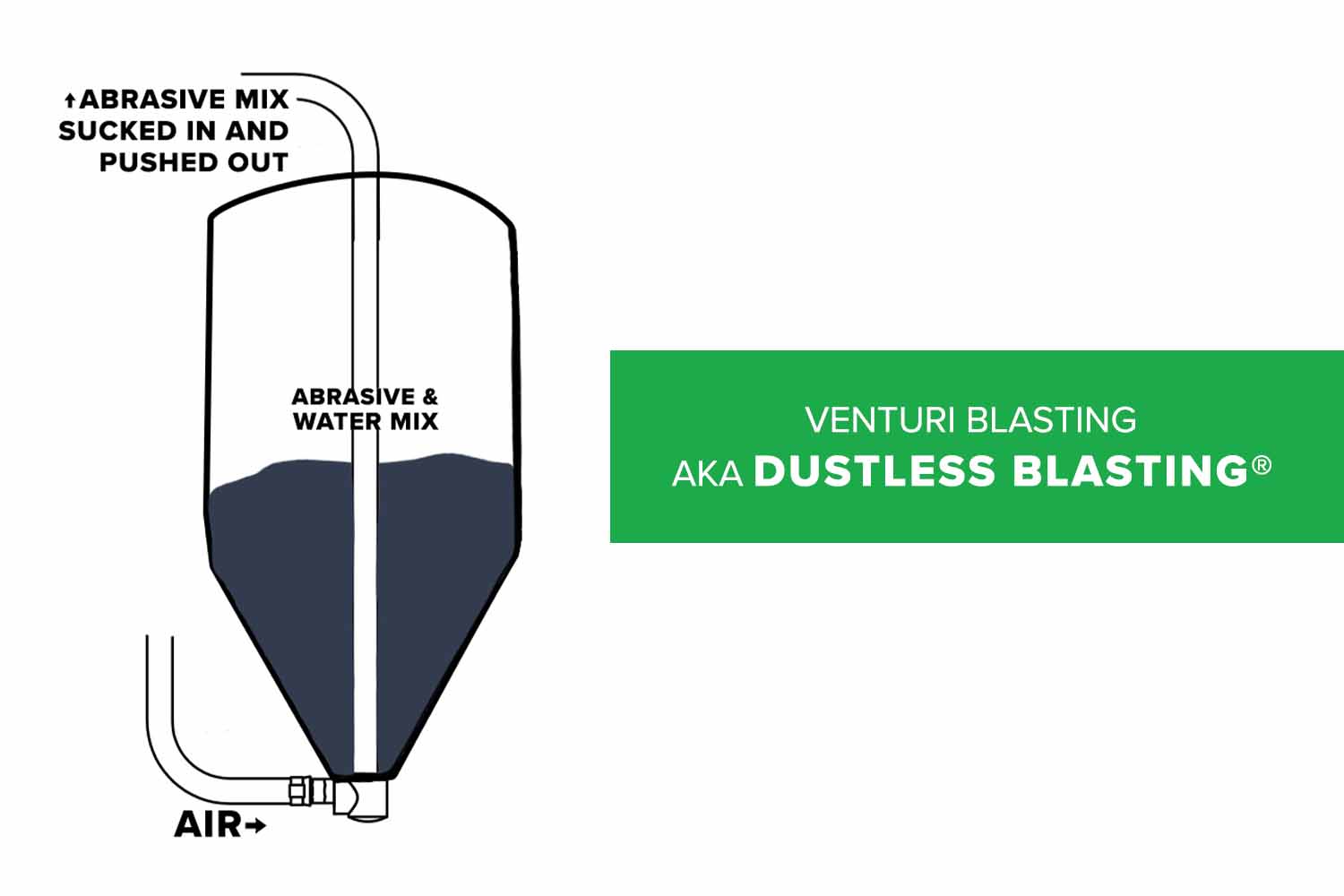

Venturi Blasting

Named after the "Venturi effect" this blast method is the technology all of our Dustless Blasting systems employ. The Venturi system stores water and blast media in the main blast chamber. From there, compressed air flows through the feed system and creates a vacuum. As a stream of high-pressure air moves through the blast pot, the vacuum from the Venturi effect sucks the abrasive media and water mixture out of the chamber and through the blast hose. Because of the nature of the Venturi system, operators are less likely to experience clogging from sinking, wet media.

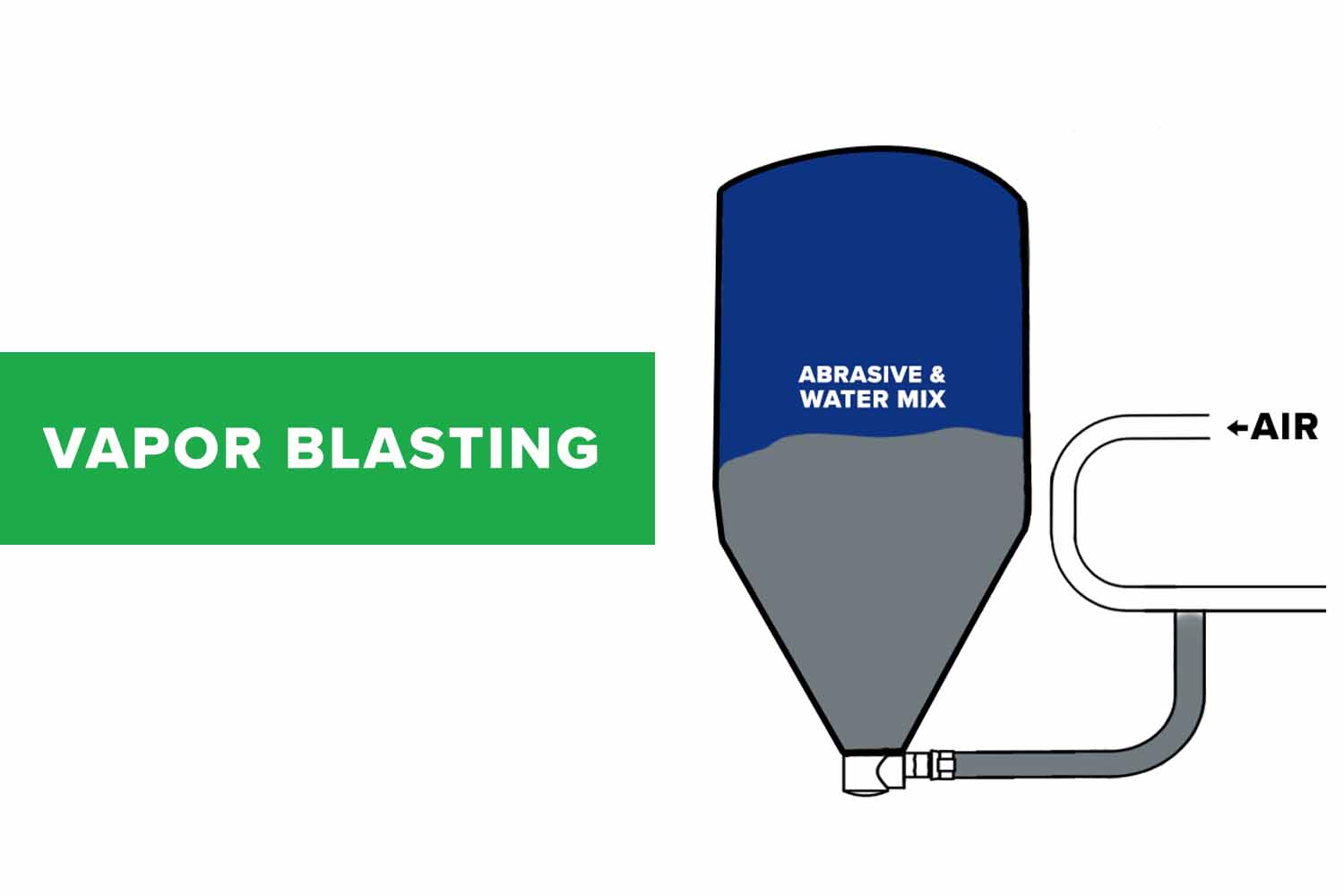

Vapor Blasting/Vapor Honing

Vapor blasting or vapor honing are two phrases used interchangeably to describe the vapor blasting process. Like other wet blasting technologies, a vapor blasting machine starts with a mixture of water and abrasive in the blast pot chamber. From there, the mixture is forced out of the chamber and to the nozzle by air pressure within the pot. This process is different than the vacuum flow effect of the Venturi technology above. A correct balance between water and media in the vapor honing machine is necessary for efficient flow. Be on the look out for media clogging during the vapor honing process, as this water/media balance may take some trial and error.

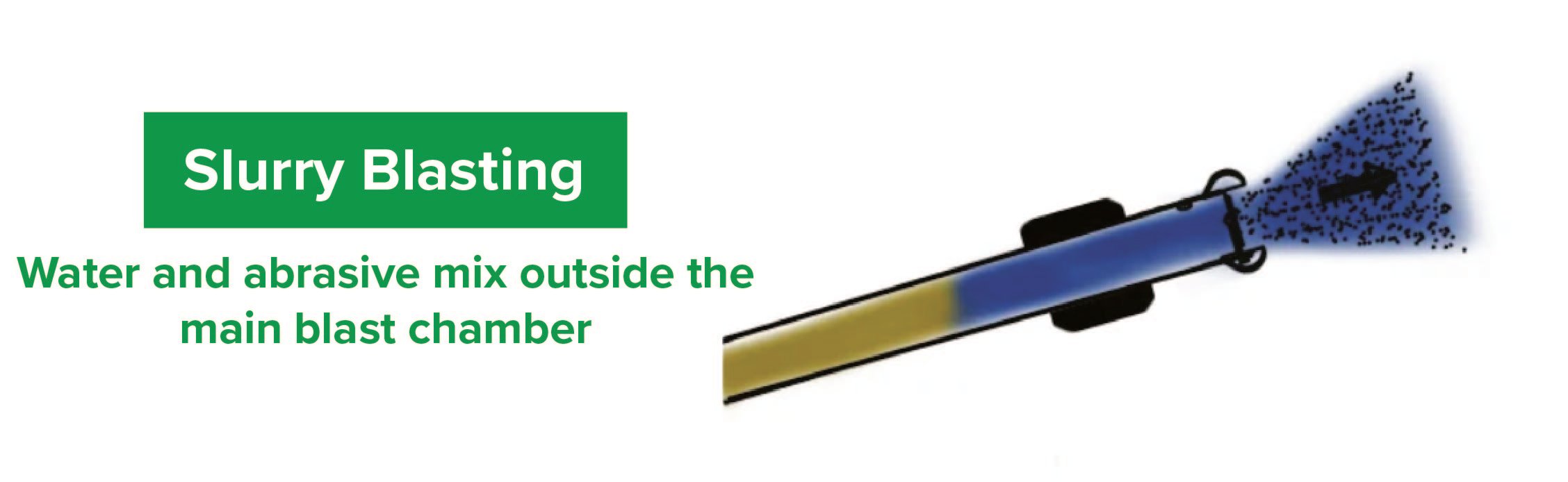

Slurry Blasting

While still utilizing a wet blasting method, slurry blasting does not start with water AND abrasive in the blast pot. The blast media is added to the blast pot alone, and water is introduced outside the chamber. There are many ways water is introduced to the media to create the slurry, but the most important note is the water and media do not combine in the main blast chamber.

Dry Blasting

The final technology or method we'll talk about today is dry blasting. Dry blasting is commonly referenced as sandblasting, soda blasting, or media blasting. Though the terms within the technology give the impression we use only a couple abrasives, dry blasting can utilize more than just sand or baking soda. The abrasive choice will vary based on application and desired end surface profile. The main difference here is - there is no water! Though we always recommend proper PPE, extra caution must be used when dry blasting to prevent inhalation of potentially harmful particles. Without the water to suppress extra dust, operators will have a lot more airborne material to be wary of.

| Note: While Dustless Blasting machines utilize the Venturi technology, our blast pots are capable of dry blasting as well. No matter the application, our multi-tech machine has your back. |

Lesson Recap

While there are numerous general terms to describe wet blasting and dry blasting, the technology of the blast method is the core of understanding a surface preparation process. Venturi blasting equipment, such as a dustless blaster, utilizes the Venturi effect to move water and abrasive through the blast pot. Vapor blasting equipment or vapor honing technologies rely on the air pressure in the blast pot to move the water and abrasive mixture through the hose and out of the blast nozzle. Slurry blasting does not introduce water to the abrasive media in the blast pot but is still a method of wet blasting. Dry blasting is a method of surface preparation or restoration that doesn't use water, only abrasive.

Does Technology Matter?

Each technology, Venturi, vapor, slurry, or dry, has its advantages and disadvantages. A choice between a wet blasting machine or dry blasting machine (or 2-in-1 with Dustless Blasting!) comes down to the application you're looking to use the tools for. For example, in the automotive industry, having a 2-in-1 machine is perfect for wet blasting the outside components to prevent heat warping and dry blasting the inside components to prevent wet media from clogging hard-to-reach surfaces.

Check out the Dustless Blasting advantage here. We manufacture our machines to deliver quality surface cleaning, no matter the application. Curious to learn more about vapor honing or blasting? Check out our other blog posts to see why wet blasting equipment might be the best choice for you.