The Better Way to Wet, Dry, & Soda Blast

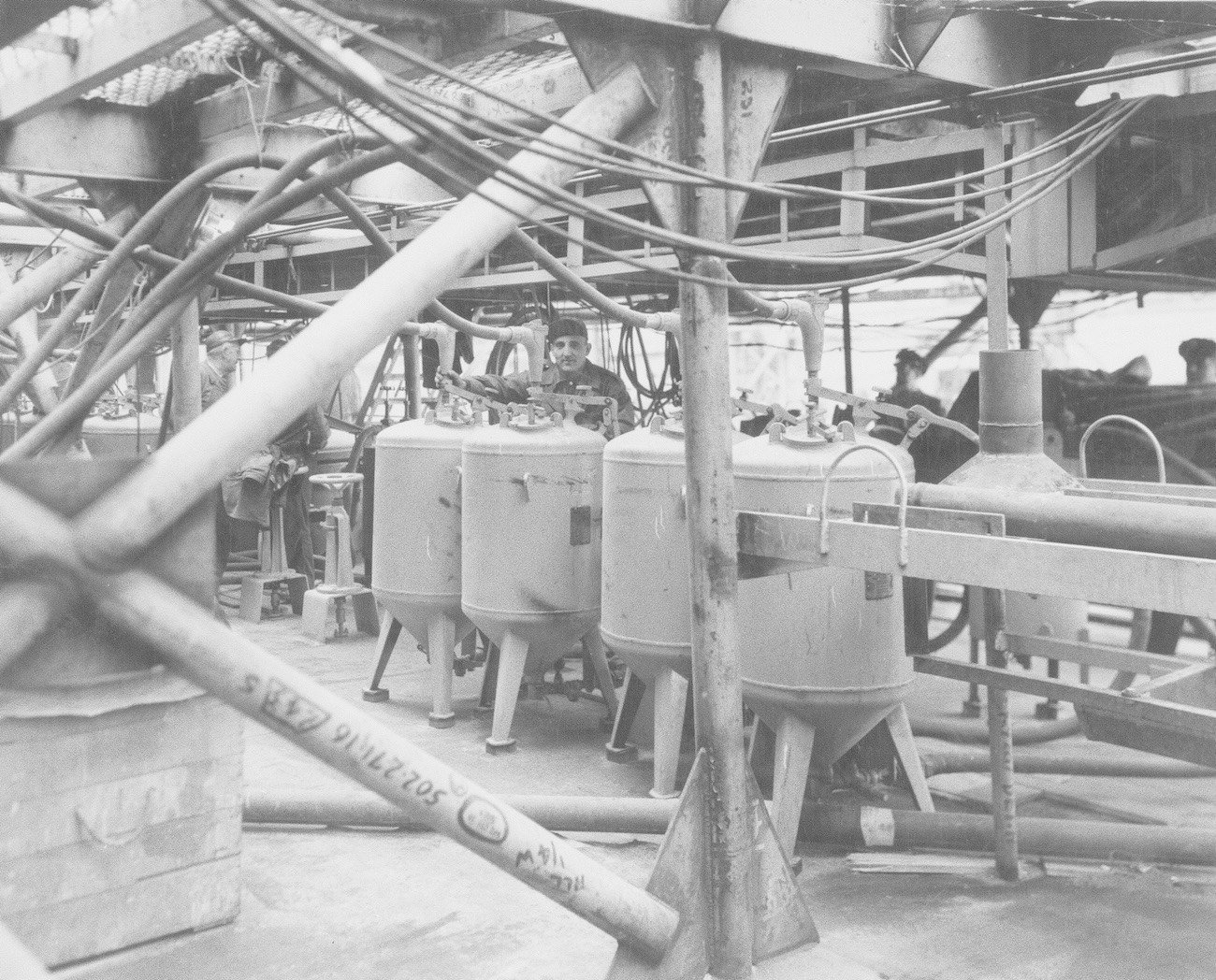

You deserve a solid return on investment, starting with reliable, long-lasting equipment. Our versatile wet, dry, and soda blast pots, proudly made in America to the highest industry standards, are backed by a lifetime warranty and rigorously tested for both performance and safety. Capable of handling almost any media, our blasters give you the flexibility to adapt your blast method to your business needs.

What is Soda Blasting?

Soda blasting is a mild form of abrasive blasting that uses sodium bicarbonate (baking soda) as the abrasive media, propelled by compressed air or water. It is effective for cleaning delicate surfaces without damaging them, as the soda is softer than most materials but harder than contaminants. This method is ideal for cleaning without altering the underlying surface, making it useful for tasks like remanufacturing, machinery maintenance, and food processing equipment.

Grounded in the Past, Leading the Future

Leading the Future of Versatile Blasting

Our equipment combines decades of experience with modern technology for reliable, durable performance. We manufacture all key components in our 70,000+ sqft Houston facility, using advanced tools like robots, plasma tables, sub arcs, and high-powered welders.

With a strong foundation in quality craftsmanship, we continuously adapt to meet the needs of the industry demands. From comprehensive mobile designs to our newest portable air drying and cooling solutions, we provide the tools you need to stay ahead in the market.

Proven, Patented Design

Grounded in the Past, Leading the Future

Using compressed air, our patented Venturi technology creates a vacuum that draws the abrasive mixture through the blast pot. Unlike traditional gravity-fed systems, the vacuum effect reduces clogging risks and provides a steady, controlled flow of both wet and dry media. Designed for versatility, our machine handles nearly any abrasive on the market, so your blast pot adapts to your business, not the other way around.

In a recent field test, a shipyard achieved a 31.82% increase in epoxy removal efficiency by switching to Dustless Blasting technology.

Proven, Patented Design

Using compressed air, our patented Venturi technology creates a vacuum that draws the abrasive mixture through the blast pot. Unlike traditional gravity-fed systems, the vacuum effect reduces clogging risks and provides a steady, controlled flow of both wet and dry media. Designed for versatility, our machine handles nearly any abrasive on the market, so your blast pot adapts to your business, not the other way around.

In a recent field test, a shipyard achieved a 31.82% increase in epoxy removal efficiency by switching to Dustless Blasting technology.

Simplified Maintenance

Grounded in the Past, Leading the Future

All of our blast pots deliver the same superior surface preparation right from the factory floor—no upgrades required. That means straightforward, no-nonsense maintenance for your business. With few proprietary parts and easy-to-access components, you can order wear parts directly from our online store and have them shipped to your shop. Service your machine on your time without the need to wait for professional installation.

Simplified Maintenance

All of our blast pots deliver the same superior surface preparation right from the factory floor—no expensive upgrades required. That means straightforward, no-nonsense maintenance for your business.

With few proprietary parts and easy-to-access components, you can order wear parts directly from our Online Store and have them shipped to your shop. Plus, you can service your machine on your time without the need to wait for professional installation.

Our Trusted Partners

Grounded in the Past, Leading the Future

We’re proud to supply reliable equipment to respected brands across various industries. From established companies to emerging leaders, our machines are the trusted choice for businesses that can’t afford to compromise.

Built for a Lifetime

Our Trusted Partners

We’re proud to supply reliable equipment to respected brands across various industries. From established companies to emerging leaders, our machines are the trusted choice for businesses that can’t afford to compromise.